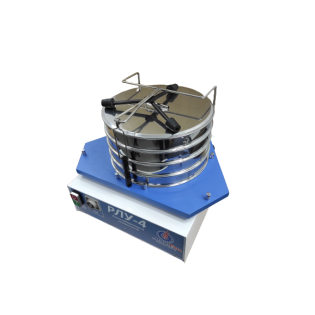

RLU-4 Laboratory Universal Sieve Analyzer

recommended for use in laboratories of grain producing, grain receiving and processing enterprises

Altair Plus Company provides warranty and after-warranty service and repair of products manufactured by the company. Warranty periods are indicated in the accompanying documentation and may vary depending on the type of product.

Payment is carried out according to the invoice issued by prior agreement with the manager of the company. You can pay an account at any bank or transfer money through another bank account.

Delivery across Ukraine of the goods ordered by you can be carried out by the cargo-transport companies “Delivery”, “SAT”, “Novaya Pochta”, “Night Express”. Delivery is carried out within 1-3x working days in the most appropriate way for a particular order at the expense of the buyer.

Sieving laboratory RLU-4 (hereinafter referred to as sieving) is recommended for use in laboratories of grain producing, grain receiving and processing enterprises for:

- determination of grain contamination by insects in explicit form; determination of weed and grain impurities, fineness and content of small grains of wheat, rye, oats, barley, millet, buckwheat, rice grain, corn;

- determining the quality of cereals: semolina, millet, rice groats, chopped rice, chopped kernels and flour in the kernel and the separation of buckwheat, chopped kernels in chopped peas;

- determine the size of flour;

- determination of the size of the feed mill grinding;

- for determining flour infection with barn pests.

Sieving can also be used in other industries in industries that use sieving with circular translational motion of sieves in the same plane.

Sieving is equipped with an electronic - mechanical timer, by means of which the device operating time is regulated.

- determination of grain contamination by insects in explicit form; determination of weed and grain impurities, fineness and content of small grains of wheat, rye, oats, barley, millet, buckwheat, rice grain, corn;

- determining the quality of cereals: semolina, millet, rice groats, chopped rice, chopped kernels and flour in the kernel and the separation of buckwheat, chopped kernels in chopped peas;

- determine the size of flour;

- determination of the size of the feed mill grinding;

- for determining flour infection with barn pests.

Sieving can also be used in other industries in industries that use sieving with circular translational motion of sieves in the same plane.

Sieving is equipped with an electronic - mechanical timer, by means of which the device operating time is regulated.

Scope of Application and Limitations of the RLU-4 Laboratory Universal Sieve

Scope of the Device:

Grain Crops and Processed Products

- All types of grain crops.

- Flour of various grades.

- Compound feeds.

- Oilcakes and meal.

Industrial Sectors for Granulometric Composition Analysis

- Construction industry.

- Chemical industry.

- Mining industry.

- Other sectors requiring particle size analysis of products

The device is universal for determining the granulometric composition of bulk materials in various fields of production and research.

Despite its versatility, the RLU-4 laboratory sieve has limitations.

It is not suitable for:

- Liquid, moist, and sticky products (dough, pastes, clays, etc.).

- Large-scale industrial sieving of big batches.

- Oversized or abrasive materials (nuts, wood chips, sand, cement).

- Pharmaceutical and chemical production requiring sterility and airtightness.

- Multi-stage fractional analysis with a large number of sieves.

Operating Instructions for the RLU-4 Laboratory Universal Sieve

Download the operating instructions ↓

| In Russian: |  |

| In Ukrainian: |  |

You can buy high-quality sieving laboratory RLU-4, as well as order laboratory equipment for other purposes in Altair Plus LLC using the address of the organization, phone numbers or the feedback form on the Contact page.

Technical characteristics of sieving laboratory RLU-4:

|

The oscillation frequency of the network package units / min

|

120/200±10%

|

|

Amplitude of vibrations (mm)

|

25

|

| Working time | from 1 sec. to 10 min. |

| Supply voltage | 220V; 50Hz |

|

Power, (kWt)

|

0,015

|

|

Dimensions:

|

|

|

Length (mm, not more)

|

520

|

|

Width (mm, not more)

|

720

|

|

Height (mm, not more)

|

700

|

|

Weight (kg, not more)

|

30

|

Set the sieve on a hard laboratory bench.

Connect the mains cable to the sifter and to the 220 volt AC network with a grounding contact. Turn on the power toggle switch on the rear wall of the sifter. In this case, the power indicator on the “START / STOP” button should light up in white.

Install on the platform the sieve packages necessary for screening type SL-1-2 with a diameter of 200 or 300 mm. in the following combinations:

- One set of sieves with a diameter of 200 mm is installed. in the center of the platform (emphasis on platform pins is not provided);

- Three sets of screens with a diameter of 200 mm are installed. offset to the edges of the platform (with focus on the platform pins);

- One set of sieves with a diameter of 300 mm is installed. in the center of the platform (with focus on the platform pins).

In each package, a bottom and no more than three screens are installed. When installing three packages, the number of screens in each package should be the same. The test sample of the product is placed in the upper sieve, after which the sieve is closed with a lid. Put a stop on the sieve cover (sieves) and install a clamp. Tighten the clamping handle tightly, but without significant force.

Set the operating time on the timer, fill in the required amount of bulk product and press the "START" button (green button on the front panel).

After stopping the sieving, remove the clamp, the stop and the bag of sieves together with the lid and bottom.

To determine the infection of grain by insects in explicit form, it is necessary to use a set of appropriate sieves with a diameter of 300 mm. And grain processing is performed according to GOST 13586.4.

When carrying out other work on the device, adhere to the following recommendations:

- Sifting of grain in accordance with GOST 13586.2-81 with exposure:

Connect the mains cable to the sifter and to the 220 volt AC network with a grounding contact. Turn on the power toggle switch on the rear wall of the sifter. In this case, the power indicator on the “START / STOP” button should light up in white.

Install on the platform the sieve packages necessary for screening type SL-1-2 with a diameter of 200 or 300 mm. in the following combinations:

- One set of sieves with a diameter of 200 mm is installed. in the center of the platform (emphasis on platform pins is not provided);

- Three sets of screens with a diameter of 200 mm are installed. offset to the edges of the platform (with focus on the platform pins);

- One set of sieves with a diameter of 300 mm is installed. in the center of the platform (with focus on the platform pins).

In each package, a bottom and no more than three screens are installed. When installing three packages, the number of screens in each package should be the same. The test sample of the product is placed in the upper sieve, after which the sieve is closed with a lid. Put a stop on the sieve cover (sieves) and install a clamp. Tighten the clamping handle tightly, but without significant force.

Set the operating time on the timer, fill in the required amount of bulk product and press the "START" button (green button on the front panel).

After stopping the sieving, remove the clamp, the stop and the bag of sieves together with the lid and bottom.

To determine the infection of grain by insects in explicit form, it is necessary to use a set of appropriate sieves with a diameter of 300 mm. And grain processing is performed according to GOST 13586.4.

When carrying out other work on the device, adhere to the following recommendations:

- Sifting of grain in accordance with GOST 13586.2-81 with exposure:

for corn - 5 min.,

for other crops - 3 min.,

- Sifting cereals in accordance with GOST 26312.4-84;

- Determination of flour size in accordance with GOST 27560-87 (sifting 8 min.);

- Determination of the size of the feed mill grinding and the content of not crushed seeds of cultivated and wild plants in accordance with GOST 13496.8-82;

- Pancake week seeds in accordance with GOST 10854-88 (to sift 3 min.).