LZM Laboratory Mill

designed for grinding laboratory samples of grain of agricultural crops and products

Altair Plus Company provides warranty and after-warranty service and repair of products manufactured by the company. Warranty periods are indicated in the accompanying documentation and may vary depending on the type of product.

Payment is carried out according to the invoice issued by prior agreement with the manager of the company. You can pay an account at any bank or transfer money through another bank account.

Delivery across Ukraine of the goods ordered by you can be carried out by the cargo-transport companies “Delivery”, “SAT”, “Novaya Pochta”, “Night Express”. Delivery is carried out within 1-3x working days in the most appropriate way for a particular order at the expense of the buyer.

With the help of a laboratory mill LZM, it is possible to effectively crush the seeds of grain, leguminous and oilseeds, various products from grain, including all kinds of raw or feed products.

The use of laboratory LZM mills is recommended for enterprises engaged in the reception or storage of grain, producing feed, processing grain factories, and any other organizations, in particular agricultural ones, where it is necessary to assess the quality indicators of various crops and their products.

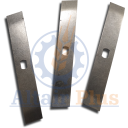

Grinding products in mills LZM is carried out with a knife made of tool steel. Due to the specialized chemical composition and unique heat treatment, the material of the cutting element has a rare combination of properties - high hardness and strength at the same time.

The capacity of the grinding chamber of the mill is made of modern high-tech polystyrene-based plastic with a high heat transfer rate, which allows the heat to be removed from the sample in a timely manner, thereby preventing moisture loss that could adversely affect the results when determining moisture.

The shaft of the engine of the LZM mill rotates at a speed of not less than 23 thousand revolutions per minute (idling). Such characteristics provide high-quality grinding, up to the particle size, at which no more than 10% of the total number of sample grains remains on a sieve with 0.8 mm mesh (with a sample weight of 20 grams).

The use of laboratory LZM mills is recommended for enterprises engaged in the reception or storage of grain, producing feed, processing grain factories, and any other organizations, in particular agricultural ones, where it is necessary to assess the quality indicators of various crops and their products.

Grinding products in mills LZM is carried out with a knife made of tool steel. Due to the specialized chemical composition and unique heat treatment, the material of the cutting element has a rare combination of properties - high hardness and strength at the same time.

The capacity of the grinding chamber of the mill is made of modern high-tech polystyrene-based plastic with a high heat transfer rate, which allows the heat to be removed from the sample in a timely manner, thereby preventing moisture loss that could adversely affect the results when determining moisture.

The shaft of the engine of the LZM mill rotates at a speed of not less than 23 thousand revolutions per minute (idling). Such characteristics provide high-quality grinding, up to the particle size, at which no more than 10% of the total number of sample grains remains on a sieve with 0.8 mm mesh (with a sample weight of 20 grams).

The main structural elements:

- mill body;

- glass grinding chamber;

- a cover of a grinding chamber;

- electric motor;

- a knife for grinding samples;

- power switch;

- power cable;

- plug.

- glass grinding chamber;

- a cover of a grinding chamber;

- electric motor;

- a knife for grinding samples;

- power switch;

- power cable;

- plug.

The mill body is made of plastic and is intended for fastening and protecting the electric motor. On the side surface of the generatrix of the truncated cone is a switch. The case, expanding downwards, has an additional protrusion at the very base, increasing the diameter of the support to increase the stability of the equipment.

A plastic cup of the grinding chamber is mounted on top of the laboratory mill body and serves as a container for the crushed components. Inside is also a knife mounted on an electric motor shaft. The edge of the glass of the grinding chamber has a thread for installing a screw cap.

The lid of the grinding chamber is made of the same plastic as the glass, and together with it forms a collapsible container, which reliably holds all the grains of the sample inside the chamber when it is intensively ground with a knife.

When connected to an AC mains, an electric motor located in the mill body develops and transmits a powerful rotation with a large number of revolutions per minute through a shaft to a steel knife located in the grinding chamber.

The knife for grinding samples has two working blades with sharp edges, which, moving at high speed, grind the components of the sample to the extent necessary for research.

The power switch is designed in the form of a key with two positions (on / off) and provides convenient and safe control of starting and stopping the electric motor, which drives the mill knife.

The power cable supplies current from the outlet to the equipment.

The plug at the end of the power cable provides reliable contact and a safe connection for the person to the power socket of the laboratory.

Scope of application and limitations of the LZM laboratory mill

Scope of application of the device:

- Cereal crops — wheat, rye, etc.

- Leguminous crops and oilseeds.

- Products of their processing — grains, cereals, mixed feed, etc., for quality analysis.

- Dry or moderately moist solid food products (moisture content not exceeding 18%).

- Materials requiring sample preparation with a weight of up to ~50 g.

It is not suitable for:

- Materials with high moisture content (all above the specified threshold of ~18%) — not recommended.

- Very large weights or large volumes of a single sample (more than ~50 g).

- Very hard materials (minerals, metals, ores).

- Materials requiring ultra-fine grinding.

Operating instructions for the LZM laboratory mill

Download operating instructions ↓

| In Russian: |  |

| In Ukrainian: |  |

You can buy a mill for a laboratory, or order laboratory equipment of the desired type in Altair Plus PE using the address, phone numbers or feedback form indicated on the Contact page.

Technical characteristics of the laboratory grain mill:?

|

Rated voltage

|

220 V |

|

Current consumption, no more

|

1 А

|

|

Current frequency

|

50 Hz

|

|

Power consumption, no more

|

250 W

|

|

Shaft rotation speed without load, not less

|

23000 rpm

|

|

Operating mode - cyclic

|

5 minutes. work, 10 minutes break

|

|

Емкость стакана

|

100 cm.³

|

|

The mass of the grinded product, no more

|

50 g

|

|

Overall dimensions (diameter x height)

|

(140 х 205), mm

|

When working with the mill in the laboratory, it is imperative to remember that when performing all operations with an open glass of the grinding chamber, including loading, emptying or cleaning, the equipment must be completely de-energized by disconnecting the electrical connector.

Typical sequence of work with the mill:

Typical sequence of work with the mill:

1. Pour the sample into the glass of the grinding chamber.

2. Dress and tighten the rotatable camera cover.

3. Plug the mill plug into a power outlet.

4. Press the switch key to turn on the mill for 30-50 seconds.

5. Turn off the equipment by changing the position of the switch to the opposite.

6. Disconnect the device completely by unplugging the plug.

7. Unscrew and remove the camera cover.

8. Pour the crushed product into the designated container.

9. Using a brush, clean the beaker and chamber lid from any adherent sample components.

2. Dress and tighten the rotatable camera cover.

3. Plug the mill plug into a power outlet.

4. Press the switch key to turn on the mill for 30-50 seconds.

5. Turn off the equipment by changing the position of the switch to the opposite.

6. Disconnect the device completely by unplugging the plug.

7. Unscrew and remove the camera cover.

8. Pour the crushed product into the designated container.

9. Using a brush, clean the beaker and chamber lid from any adherent sample components.

After grinding all the samples, it is necessary to clean the accessible surfaces of the laboratory LZM mill with a napkin.